Many skills are required to be a successful mechanical designer. You not only need to have an understanding of Solid Mechanics, Fluid Mechanics, Thermodynamics, heat transfer, and Dynamics. You need to be able to apply them in a way that will be economical as well as effective. In order to be a successful mechanical designer you will need to be able to follow a design process.

When designing a mechanical system a mechanical engineer is generally concerned about the production and processing of energy. This can include ways to improve production, ways to improve transportation, and techniques to improve automation, just to name a few. As mentioned above a range of disciplines will be required. For example the design of simple bearing would require knowledge of fluid flow to choose the correct lubrication. It could also require that you have knowledge of heat transfer if the bearing is used in a high speed application where there’s a possibility of friction causing heat build up. You will also need to be able to choose the correct material to make sure it can withstand the applied loads without failing. Just to name a few.

Design

When create a design you need to formulate a plan that will either satisfy a specific need or to solve a certain problem. You will need to see if the plan can result in the creation of something that can be procured with current technologies.Plus, you will need to make sure that the product is functional as well as safe, reliable, and competitive. Also, you will have to make sure that the product is usable as well as marketable. Due to all of these facts design is a highly innovative as well as iterative process.

There is also a decision making process that needs to be considered. Quite often you will have to make decisions with only a little information, while rarely have all of the information that you would need. While sometimes you might have contradictory information where you will have to decide which path makes the most sense to follow. Decisions will have to also be made on the fly sometimes in order to meet a deadline, and than in the future that decision will have to be analyzed again to determine if it was right or if there is a better option once more information becomes available through testing. Either way a design engineer needs to comfortable as well as confident in the decision making a problem solving role.

Communication is also extremely important when working on mechanical designs. Most likely in the real world you will be working on project with a team. Your teammates most likely will be from other disciplines, such as electrical, or chemical backgrounds. They will have their own concerns with the overall design. Due to this every designer will need to communicate effectively to make sure that the product works well mechanically and electrically, or mechanically and chemically, etc.

Design Process

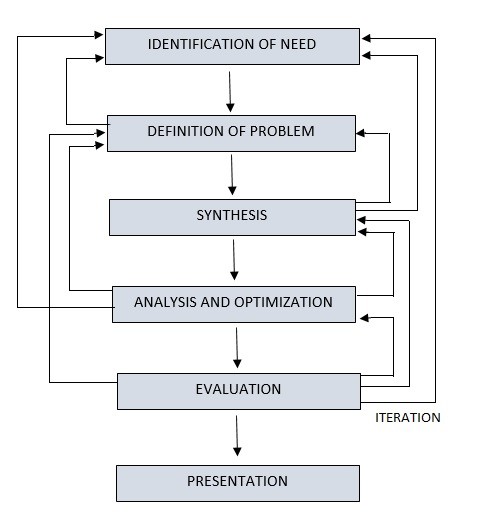

Below is an image of what a typical design process follows.

When starting a design you need to Identify a need. This is important because without a need there is nothing to base the initial design off of. Identifying a need isn’t always a simple process due to the fact that it can arise from a vague discontent, a feeling of general uneasiness, or possibly sensing that something just isn’t quite right. Do these facts a need is often not evident at all, but is instead triggered some particular adverse circumstance or possibility a set of random circumstance that could have occurred almost simultaneously.

Once a the need has been identified now you need to define the problem. Defining a problem is more specific then identifying a need. Due to this fact when defining a problem you must include all specifications that will be part of the design. After defining all of the specifications you might stumble upon another need, which if that is fact you would repeat the process of identifying the problems for those additional needs until you and you design team felt that all specification for the design have been met.

After all of the specifications of the design have been met you will move on to synthesis. First, you would synthesis a scheme to connect possible system elements. During this process, various schemes will be proposed to investigate and quantify an established metrics. This will allow the design team to determine if the expected performance of the system will be satisfactory as well as hypothesis how well it might perform. As this progresses more schemes will be developed. Each of these schemes will need to analysed against each other to determine which scheme is most likely to solve the initial problem and satisfy the initial need. Schemes that are most likely to succeed will be moved into analysis and optimization. After evaluation of the analysis, schemes that do not perform well during analysis will either be revised, improved, or discarded.

The design process is highly iterative meaning that these steps will be repeated a number of time before the design team is satisfied that their design meets the team’s requirements as well as is competitive with the current market. Once this happens the design team would than have to present their progress on their design so that management can determine if the design is ready to move to market, if the design needs to be improved, or if the design is no longer worth pursuing and is instead canceled. Due to this fact, having an excellent presentation is imperative, because a poor presentation could stop what could have been a ground breaking invention in its tracks and instead giving your competition the opportunity to discover it instead.

Below is a list of the design considerations that should be considered while designing.

- Functionality

- Strength and Stress

- Deflection and distortion

- Fatigue

- Environmental Corrosion

- Safety

- Manufacturabilty

- Maintenance

- Reliability

- Vibration

- Size and Weight

- Marketability