After choosing a motor you may decide that you want to have the wheels of your battlebot set to a specific torque or perhaps you might want to have the weapon that a motor is driving spin at a certain or RPM. In order to do this you will need to add gears to the system. There are three general ways that you can gear a system. First, you could use actual gears. Second you could use sprockets and chains. Finally, you could use a belts and pulleys. Each methods have their advantages and disadvantages.

Gears

First, let talk about actual gears. Gears are cylindrical parts that have teeth that mesh together to drive each other. There are a few different gear types that you can use. First, the most common type of gear that can be used is the spur gear. The spur gear is a gear that has its teeth cut into it parallel to its axis of rotation. Refer to the image below.

Spur gears generally are very noisy gears when they run. However, they are very efficient at transferring power with a typical efficiently of 98% to 99%.

The next type of gear that I would like to mention is the helical gear. The helical gear is very similar to the spur gear except instead of the teeth being cut into the gear surface parallel to its axis of rotation it is instead cut at a certain angle. The advantage of helical gear is that they are much quieter than a spur gear and they can either mesh together parallel to their axis or they can be meshed together at an offset angle that is dependent on the angle of the gear teeth. Refer to the image below.

The disadvantage of these gears is that they are more expensive than spur gears and they require a thrust bearing. They are also less efficient at transferring power than the common spur gear, with an efficiency ranging between 50% to 90%.

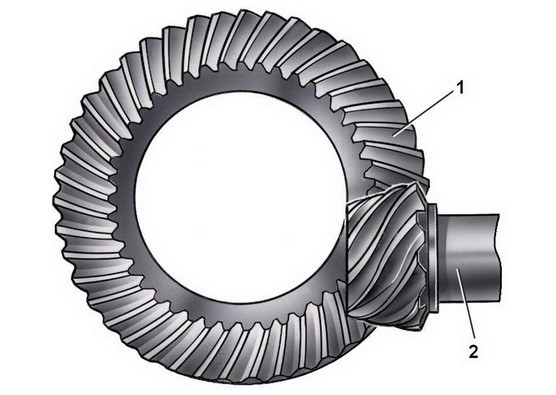

Now if you are interested in changing the angle of the drive system you will need to use a bevel gear. Bevel gears are similar to spur gears in the way the teeth of the gear mesh, except the teeth are cut on an angled face to change the angle of the drive. Each meshing gear is half the total angle. The axis of these gears must intersect to allow the bevel gears to mesh correctly. Refer to the image below.

Next, if you want to change the angle of the drive when the axis of gears are nonparallel and nonintersecting you can use a hypoid gear. Refer to the image below.

Finally, the last type of gear that I would like to mention is the worm gear. A worm gear setup consists of two different types of gears. The first gear is the worm gear, and the second is the worm. What make worm gears unique is that the worm can drive the worm gear but the worm gear can’t drive the worm. This allows this system to lock up when there is force on the output of the system. Another, interesting fact is that for every rotation of the worm only one tooth of the worm gear will move. This means you can achieve very large gear ratios inside a small area. Some disadvantage are that worm gears tend to be very inefficient with efficiency ranging between 40% to 85%. They also can only mesh perpendicular to each other. Refer to the image below.

Now for all of the type of gears that were mentioned it is important that you select gears that have the same pitch otherwise they won’t mesh together correctly and will instead jam or break.

The advantage of using gears instead of sprocket and chains or belts and pulleys is that they are typically more efficient than the other two. They also cannot slip since they are making direct contact with each other. Finally you can change the direction of the drive, to make it easier to fit a motor into a tight space.

The disadvantage of using gears is that they are heavy, they have to be assembled close together since they need to make contact, they are expensive, and you have to use lubricant to prevent the metal from overheating or galling which could cause the gears to bind.

In addition, this isn’t an advantage or a disadvantage, but the rotation of meshing gears will reverse. For example if the drive gears is rotating in a clockwise direction the driven gear will rotate in the counter-clockwise direction and vice versa.

Generally, it is better to buy a gear box instead of individual gears, since it is usually cheaper than buying individual gears and all of the other components that will be needed to make them mesh together. Also, all of the design work has already been done for you and the gear box should already have the required lubricant inside of it to prevent overheating and binding.

Sprockets and Chains

Sprockets and chains are pretty simple drive systems that are commonly used. This system typically consists of two sprockets of different size that are driven by a chain. These systems will also typically have an idler, which is a third sprocket that is on movable arm with a spring on it to create tension on the chain to prevent the chain from falling off the sprockets. The idler has no effect on the gear ratio of the system. It can, however, effect the efficiency of the system, since its adding friction. Refer to the image below to see a common sprocket and chain system.

Just like with gears, the pitch of the sprockets have to match the pitch of the chain so that the chain will mesh with the teeth of the sprocket.

The advantages of using a chain sprocket drive is for one the system is light weight. Another advantage is that the object that the motor is driving doesn’t have to be close to the motor since the chain can span the distance between the two. Finally, chains are less likely to break than a rubber belt, and they won’t slip if they are secured correctly.

The disadvantages of a chain sprocket drive is they do not transfer power as well as gears do. If it isn’t designed correctly the chain could fall off the sprockets. Finally, the axis of rotation and face of each sprocket have to be in parallel with each other, which means the direction of the drive cannot be changed.

Belt and Pulleys

Belt and pulleys are a third method that can be used to transfer the power from the motor to the driven object. There are three types of pulley belts systems that I will mention. They are flat belts, V belts, and timing belts.

Flat belts are flat pieces of materials that are placed under tension to drive two flat cylinders. These types of belts are extremely inefficient and can slip very easily. Having a belt that can slip, however, can be an advantage when you are trying to protect a more expensive or important part of the drive system. Refer to the image below to see a flat belt pulley.

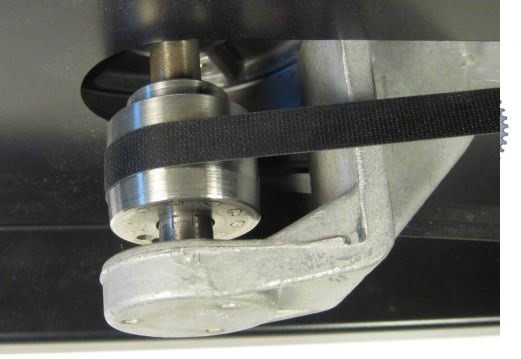

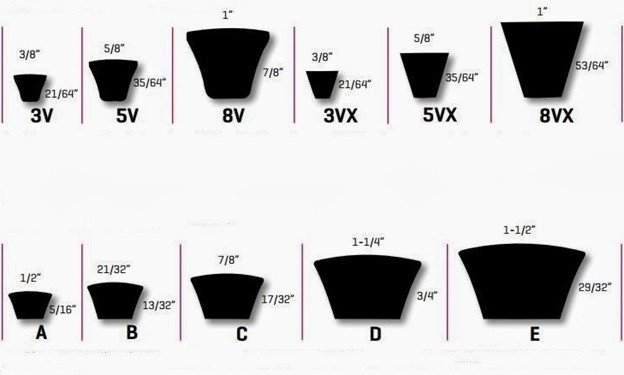

The next type of belt system is a V belt pulley system. The V cut in the pulley will allow the belt to wedge itself into the pulley. This will decrease the likelihood that the belt will slip which will help increase the efficiency of the system. Below is an image showing different size V belts.

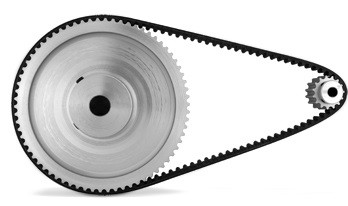

Finally, the third type of belts and pulley system are timing belts. Timing belts have rubber teeth on the inside of them that will mesh with cut outs on a timing pulley. Due to this fact, the pitch of the pulleys will need to match the pitch of the belt. The fact that the belts will mesh with the pulley will greatly decrease the chance that the belt will slip. Due to this fact these are the most efficient belt pulley setups. Refer to the image below.

The advantage of using pulleys and belts is that they are cheaper to buy than gears. They are also light weight. Also, the fact that they can slip can help protect more expensive parts closer to the motor from high shocks to the drive system.

The disadvantages are the following. Depending on the type of pulley belt system chosen they can be very inefficient when transferring power since they can slip. Belts can also break easier than chains would causing the drive to fail. Finally, like chains and sprockets the axis of rotation, and face of each pulley have to be in parallel with each other, which means the direction of the drive cannot be changed.

Gear Ratio

Besides understanding the different devices that you can use to create a drive system, you also need to have an understanding of what a gear ratio is. First let’s talk about some terminology. Gearing up a system means you are using gears to increase the output RPM while sacrificing torque. Gearing down a system on the other hand means that you are decreasing the output RPM to increase the output torque. This is important to know because it is possible to gear system up to much so that it takes a considerable amount of time to reach those fast RPMs. It also possible to gear a system down too much to the point that even though it is going to act like a tank and be able to push through anything it will be dead slow.

In order to calculate the gear ratio you would take the ratio of the two diameters of the output and input gear if you are dealing with pulley or you would take the ratio of the number of teeth if you are dealing with gears and sprockets.

For example if you have an input pulley with a 1 inch diameter driving a pulley with a 3 inch diameter, and the motor that is driving the system has an output of 30 in-lb of torque and a maximum RPM of 2000, what would be the torque and RPM of the 3 inch pulley?

First the gear ratio would be 1 inch over 3 inches. This will result in a gear ratio of 1/3. Now remember that when the system is geared down, the torque will increase while the RPM decreases. So to calculate the torque we would divide the motor torque by 1/3 which means we would be multiply the motor torque by 3. This will result in a torque of 90 in-lb at the 3 inch diameter pulley. Now to calculate the RPM we would multiply the motor RPM by the gear ratio of 1/3, which means we would be dividing the motors RPM by 3. This would result in the 3 inch pulley spinning at an RPM of 667 RPM. Refer to the equations below for simplification.

$Gear Ratio = \frac{1}{3}$

$Output~Torque = \frac{30 in-lb}{1/3} = 90 in-lb$

$Output~RPM = 2000 RPM \left(\frac{1}{3}\right) = 667 RPM$

All of these calculation assume 100% transmission of power, which in real life will not happen. Instead only a certain percent of the motors power will be transmitted which means the calculated values could be less than expected depending on the losses.